Stutzen-Isolatoren: Manufacturers of Pintype Insulators in Germany

by Matt Grayson

Reprinted from "INSULATORS - Crown Jewels of the Wire", June 1979, page 10

Preface

After a trip to France in 1973, during which I recovered about fifty French insulators, I

became interested in European insulator history. Language and distance made for

significant handicaps; though I was able to obtain some data from a number of

companies currently manufacturing European insulators after consulting the New

York trade ministries of each country. They supplied me with the addresses of

the manufacturers in their respective countries and, to each of these addresses,

I wrote, in English, requesting catalogs, historical information, etc.

The

results varied. The reply rate was about fifty percent; though only half of

these supplied data on pintype insulators. Of them, one company manufactures

glass and five porcelain. All subsequent letters to these companies went

unanswered. Still, in some cases, this information does illuminate some items

which have previously appeared in Crown Jewels and with the seemingly increased

interest in foreign insulators, will answer some questions which have yet to be

published.

This information was supplied in the first half of 1974, so that it

is probably somewhat out of date. If anyone cares to follow up, as my personal

interest in foreign insulators has waned, I would be most happy to supply them

with the addresses of the companies and trade ministries.

In this, and the

following two issues, I will describe the items produced by companies operating

in Germany, Spain and Italy.

The German insulator industry is very much alive

today. They are producing a number of unique EHV types, as well as more

traditional designs, in porcelain. I received information from three companies

producing pintype insulators, though only two provided catalog data. The

following article provided by RWI outlines the early history of insulators in

Germany:

DEVELOPMENT OF THE OVERHEAD-LINE-INSULATION IN GERMANY

by Ed. Diehl,

Stuttgart and G. Reverey, Heidelberg

The development of the

overhead-line-insulation in Germany began in the middle of the last century. The

first overhead lines were telegraph-lines on wooden poles and the first

insulator was a porcelain pin-type insulator. This pin-type insulator was

developed in the year 1850 by Werner von Siemens as a bell-shaped insulator

(fig. 1). In the following years this insulator got an additional petticoat to

improve the service reliability (fig. 2).

A telegraph-line equipped with

this kind of insulator was used by Oscar von Miller and Marcel Deprez in 1882 on

the occasion of the world's fair in Munich to transmit a power of 1.5 hp from

Miesbach to Munich over a distance of 57 km with a voltage of 2000 volts, This

was the first German d. c. high voltage long distance transmission.

The next

stage of the bell-shaped insulator was the oil-groove insulator (fig. 3). The

lower part of the bell-shaped coat was bent inside and in this way forming a

groove which was to be filled with oil. The oil groove should prevent the

formation of a coherent humidity film in rain and fog and thus to make a flow of

current on the insulator surface impossible. Later on an improved type got some

more such grooves. The oil-groove insulator can be regarded as the first

anti-pollution insulator.

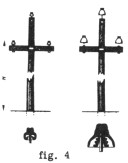

With oil-groove insulators the wood pole overhead-line

from Lauffen to Francfort was equipped over a distance of 178 km on which in

1891 a power of 210 kW at a voltage of 15000 volts was conveyed during the

international electrical fair in Francfort (fig. 4).

[This as the first type of

insulator proposed for the Niagara Project in the early 1890's]

This

transmission line was the first one with three-phase a. c. over a great

distance. The efficiency of the d. c. transmission from Miesbach to Munich

compared with the three-phase a. c. one from Lauffen to Francfort had risen

from about 23% to about 75%.

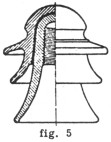

Conveying of energy with three-phase a. c.

of high voltage made fast progress and the insulation had to meet the always

growing requirements. Main problems became the puncture- and flash-over voltage

of the insulators. 1897 arose the delta pin-insulator (fig. 5) and subsequently

the wide-coat-insulator with greater flashover and puncture-path. For high

voltages it was necessary to cement insulators of several parts. For the

stability of the cementing could not be guaranteed a stronger delta-insulator

was developed (fig. 6) which already could be produced as one piece. While one

used with the first pin-type insulator the excellent compressive strength of the

ceramic material the stronger delta insulator however had because of its short

pinhole to withstand a cantilever strength. The delta-insulator was developed

for transmission lines up to 30,000 volts. Three-phase a. c. grids with such

rating voltages have already been in operation at the change of the century.

The

erection of big power stations at coal mines between 1910 and 1920 and conveying

energy to the consumption centres far away required some more powerful

transmission lines. For insulating such high voltages the pin-type insulator was

no longer qualified. Also the stacking of pin-type insulators was not reliable

enough and too expensive. The pin-type insulator therefore was superseded by the

suspension insulator.

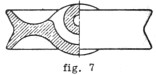

The first suspension insulator was invented by Hewlett in

1907 in the USA (fig. 7). Two types of this insulator -- a suspension and a dead

end type -- have been developed. The porcelain was only stressed by compression.

The single units were connected by metallic rope U-Iinks which were threaded

through curved tunnels in the porcelain disc. Thus the application of high

voltages and the erection of towers with greater spans have become possible.

The

Hewlett insulator stood the test in Germany, too. Detrimental, however, was the

metal loop which frequently lead to rupture by corrosion. After the Hewlett

insulator followed several other types of suspension insulators which were

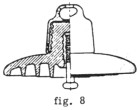

developed as cap and pin type insulators simultaneously in America and Europe.

For an insulator string the units were connected by caps and pins. The first

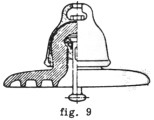

type of them appeared in 1908 (fig. 8). For taking up the pinball a cylindrical

or conical hole was used in America while in Europe a relieved pinhole was

preferred (fig. 9). Within the insulator the ceramic material was stressed by

compressive, cantilever, and transverse strength. In Germany many different ways

were tried to construct the pin hole and the pin ball fastening.

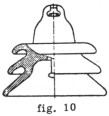

Increasing industrial contamination and salt deposit at the sea coasts led to

numerous types of cap and pin-type insulators. Long creepage distances and good

self cleaning properties became the basic requirements for the construction. In

Germany in areas with industrial contamination the deep shed insulator has stood

test well (fig. 10).

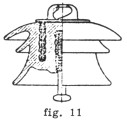

An intermediate stage of the normally with an outer cap

provided suspension insulator was the insulator with the cap inside (fig. 11).

By inserting the cap into the insulating part the flashover voltage should be

improved. With chains of such suspension insulators the first German 110 kV

transmission line with three phases a. c. from Lauchhammer to Riesa was

insulated. The overhead line with a length of 56 km was also the first overhead

line of this rating voltage with towers in steel lattice construction in the

kind of the suspension-wide-span-length-system in Germany. With two circuits

40,000 kW were transmitted. Later on instead of the cemented-in-cap, a pin ball

was used. Both kinds of inside cementing were left soon afterwards.

The

impetuous extension of the German high voltage grid after World War I resulted

in requirements of a greater reliability as for power transmitting. Referring to

German experiences the crucial shortcoming of all types of suspension insulators

was that they were not puncture proof. Cracks in the thin walled head part of

the insulating material by mechanical stress led to electrical punctures. The

constant control of single units under service and the replacement of the defect

insulators on dead lines were very disadvantageous for operation and led to the

search of a puncture proof insulator.

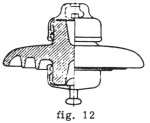

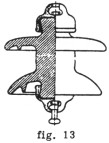

As a first kind of a puncture proof

insulator appeared in 1910 the double cap insulator with one disc (fig. 12).

Further development presents the solid core insulator with two sheds (fig. 13),

from which the Motor-insulator was created in the year 1917 by Motor-Columbus

AG in Switzerland.

In the beginning the upper disc has been made from tin

as a protection against rain, later on however it was manufactured from

porcelain, too. This two-shed-insulator could be regarded as a puncture proof

insulator because of its long stretched solid core. The porcelain being stressed

on tensile strength was very exacting to the manufacturing process at that time.

The two-sheds-solid core insulator is from 1925 on favoured for insulating

overhead high voltage lines with chains of several units. Besides these types

the cap-and-pin insulator has been used up to 1945.

1929 in Germany the first

220 kV-transmission-line was put in operation, the first one in 380 kV followed

1957. On account of the good experiences with the puncture proof solid core

insulators one strived for always longer units of insulators, for the high and

highest voltage lines. 1938 one succeeded by means of the de-airing pug-mill and

automatic trimming machines to manufacture homogeneous clay rods free of

defects. By exactly controlled firing one could produce a long rod insulator

which length was sufficient to insulate 110 kV overhead lines (fig. 14). 220 kV

lines could be equipped with two units, 380 kV lines with three such units. For

areas of extreme pollution appropriate types of long rod insulators have been

developed, which are up to all standards after investigating the contamination

flash over during the last twenty years.

The long rod insulator being puncture

proof therefore the aspect of the mechanical strength is well in the fare. With

the development of super strong ceramic material this problem has been solved.

A

special advantage by using of long rod insulators also can be seen in the fact

that compared with the cap and pin type insulators, as the case may be, a great

number of intermediate connecting hardware can be omitted which represents end

points of cascading arcs. All the long rod insulators are provided with arcing

devices which guarantee a nearly complete protection against power arcs.

The

operation experiences with puncture proof solid core and long rod insulators

gathered during several decades have led to the result that this kind of

insulation is today the only insulation of overhead lines. On secondary lines

non puncture proof pin-type and suspension insulators have been displaced by

puncture proof solid post and rod types. On the high and highest voltage

overhead lines the long rod insulator is the only kind of insulation. The long

rod type had its way also in other countries of Middle Europe and the other part

of the world is increasingly interested in it.

The advantage of the

one-piece-long-rod-insulator, especially its short nominal length by omission of

the intermediate connecting hardware and thus suppression of cascading arcs,

incited to develop a one-piece insulator for 220 kV. Such insulators are in a

great number in operation since more than 15 years, with good success. It is

intended to start in 1973 in Germany with a two-piece insulation for 380 kV Lines,

also it will be the year of birth of the one-piece-insulator for 380 kV.

The following are the companies that are producing pintype insulators today,

along with a description of their insulators:

Rheinisch-Westfalische Isolatoren-Werke began producing porcelain insulators in 1949, on the site of the Royal

Ammunition Factory. Their production consists of a full line of porcelain

insulators: long-rod, station post, conductor-rail, bushings, pintypes, egg and

shackle. Apparently the bulk of their production is devoted to transmission line insulators, most notably the "Langstab" or long-rod insulator.

These consist of a solid porcelain post with metal fittings as shown in figure

14.

All information I have on their insulator line is related to the long rod

and station type insulators. The catalog I have shows only these two varieties,

though it has dividers for all of the aforementioned types. A photograph in the

catalog shows brown long-rods marked with their trademark (shown above left) in

what appears to be white underglaze. I would assume this trademark is used, in

some form, on their pintypes as well.

Rosenthal Stemag Technische Keramik

manufacturers a wide range of industrial ceramics including: insulators,

grinding balls, laboratory ware and electronic ceramics. They produce a full

line of insulators: power, railway, telephone, telegraph, and porcelain terminal

blocks, sockets, and knobs. Rosenthal is one of the world's largest industrial

ceramic manufacturers and is a daughter company of Rosenthal; who, among other

products, produces high quality porcelain (china) dinnerware. Their shops are

located throughout Europe.

Rosenthal Stemag was founded in 1971, through the

merger of three separate divisions: Steatit Magnesia, Rosenthal Isolatoren and

Rosenthal Technische Werke. Rosenthal Isolatoren is the division which

manufacturers pintypes.

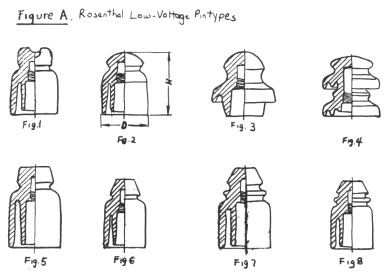

The catalogs I have show long-rod and pintype

insulators (figures A and B).

Figure A shows low voltage pintypes. Numbers one

through four show typically European styles, though I have never seen an

insulator (transposition) similar to the one shown in four. Perhaps these were

produced for export. Numbers five through eight are designed to British

specifications and can be "screwed directly on the pins." The sizes in

which these are cataloged are tabulated in Table 1.

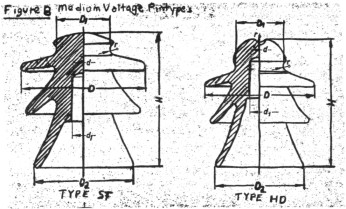

Figure B shows the typical

pintype insulators (Stutzen-Isolatoren) for voltages up to 35 Kv. The sizes in

which these are cataloged are shown in Table 2. Note that these are essentially

the same as the Delta insulator first designed in 1897. The marking they employ

is most likely some variation of the trademark shown at right.

Kronacher

Porzellanfabrick, Division of Stockhardt and Schmidt-Eckert was the final

company to supply me with information. The catalog sheets I have show long-rod,

pintype, guy-strain and line-post insulators. I have no historical information

regarding Kronacher.

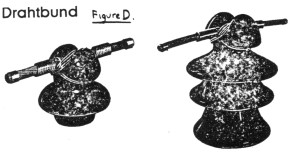

Their pintypes are shown in figures C, D, and E.

Figure C

shows the N-95 which is similar to the N-95 cataloged by Rosenthal (Dimensions,

Table 3). except it has a cable top designed for a special form of tie wire

(figure D).

They also catalog a traditional ST insulator (figure B) in exactly

the sizes shown in Table 2. Apparently, this is a European standard design.

Table 1. Rosenthal Low-Voltage Pintypes

|

Figure

|

D |

H |

Type |

Standard± |

|

1

|

3-3/8 |

5- 1/2 |

RM 1 |

|

|

1

|

2-3/4 |

4 |

RM 11 |

|

|

1

|

2-3/8 |

3-1/8 |

RM 111 |

|

|

2

|

3-3/8 |

5-1/8 |

RMk 130 |

DIN 48 140 |

|

2

|

2-3/4 |

3-3/4 |

RMk 95 |

DIN 48 140 |

|

2

|

2-3/8 |

2 |

RMk 75 |

DIN 48 140 |

|

3

|

2-3/8 |

2-3/8 |

N 60 |

|

|

3

|

3-1/8 |

3-3/8 |

N 80 |

|

|

3

|

3-3/4 |

3-3/4 |

N 95 |

DIN 48 150 |

|

4

|

4 |

4-3/4 |

RMd 120 |

DIN 48 141 |

|

4

|

3-3/8 |

3-1/2 |

RMd 90 |

DIN 48 141 |

|

5*

|

3 |

4-3/4 |

#1 fig 40 |

BS 16: 1949 |

|

6*

|

2-3/8 |

4 |

#2 fig 41 |

BS 16: 1949 |

|

7*

|

3 |

4-3/4 |

#7 fig 43 |

BS 16: 1949 |

|

8*

|

2-3/8 |

4 |

#8 fig 44 |

BS 16: 1949 |

* can be screwed directly on pin

+ DIN is the German standardization org.

NOTE: All measurements have been converted from mm to inches

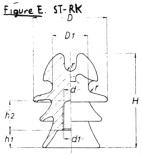

Their type ST-RK insulator (figure E, dimensions table 4) is modeled after the

traditional ST insulator but has a special "RK" cable top. They also

catalog two variations of the ST-RK with cemented in bolts similar to American

style line-posts. The standard German glaze, brown, appears to be used on these

insulators.

The markings employed are most likely variations of the trademark to

the right.

Next Month: Glass insulators of E.S.A. (Spain)

Table 3. Kronacher N-95-RK

| Type |

H |

D |

| N95-RK |

3-3/4 |

3-3/4 |

Table 2. Type ST and HD Pintypes

|

Type*

|

D(1) |

D |

D(2) |

H |

|

ST 10+

|

2-3/4 |

5-3/8 |

4-3/8 |

5-1/8 |

|

ST 15+

|

3-1/8 |

5-7/8 |

4-3/4 |

5-7/8 |

|

ST 20+

|

3-3/8 |

6-7/8 |

5-3/4 |

7-1/4 |

|

ST 25

|

3 1/2 |

8 1/8 |

6 1/2 |

8 1/2 |

|

ST 30+

|

4 |

9 |

7 1/4 |

9 7/8 |

|

ST 35

|

4 1/4 |

10 1/4 |

8 1/4 |

11 3/8 |

|

HD 3

|

1 7/8 |

3 5/8 |

2 7/8 |

3 1/2 |

|

HD 6

|

2 1/2 |

4 3/4 |

3 3/4 |

5 1/8 |

|

HD 10

|

2 3/4 |

5 1/4 |

4 3/8 |

5 3/4 |

|

HD 15

|

2 3/4 |

5 7/8 |

4 3/4 |

6 1/2 |

|

HD 20

|

3 3/8 |

6 7/8 |

5 3/4 |

8 1/8 |

|

HD 25

|

3 1/2 |

8 1/8 |

6 1/2 |

9 1/2 |

|

HO 30

|

4 |

9 |

7 1/4 |

11 |

|

HD 35

|

4 1/8 |

10 1/4 |

8 1/4 |

12 5/8 |

* All supplied with lead thimble

+ To Din 48004

Table 4. Kronacher Type ST-RK

|

Type

|

H |

D |

D(1) |

|

St 10 RK

|

6 7/8 |

5 3/8 |

2 1/2 |

|

ST 15 RK

|

7 5/8 |

6 1/8 |

3 |

|

ST 20 RK

|

9 |

6 7/8 |

3 |

|